Electronic product design is a service we have great experience in at Idea Reality. Although the process is often seen to be convoluted and technical, our expertise and uniquely tailored process allows us to guide our clients through the design process with confidence. Most electronic projects that we work on progress through a similar design process to that of non-electronic projects however there are a few key differences and considerations that set these two types of projects apart – something that we will explore in this blog post.

So, what is Electronic Product Design?

Electronic Product Design plays a key role in shaping the way we interact with technology. Although it still includes the traditional principles of product design such as sketching and CAD modelling, it also involves the integration of hardware, firmware, and user experience to create desirable and innovative electronic devices which are so important in today’s world. The process also requires specialised knowledge of electronic engineering as well as firmware and software development, areas we have covered through our various electronics teams. Bringing together the physical and digital requires expertise in embedded systems – something Idea Reality is great at achieving.

Electronic Product Design Process

Creating an electronic product with a full-service product design company like Idea Reality has its advantages over working with an independent electronics hardware developer. The key benefit is a joined-up design process ensuring the product mechanics, aesthetics and electronics are seamlessly integrated together resulting in a beautiful user-friendly product.

Working with a single cohesive multi-discipline product design team that can cover all core design requirements means the development costs and time frame are also likely to be reduced thanks to the efficiencies and internal project management.

In terms of the electronic product design process stages you can see a full design process map here. The key additions over a regular non-electronic product design process are:

Feasibility and Research

If the electronics contain unknowns and there is not clear specification from the outset then a feasibility study may be required to analyse the potential technologies available, options to consider and risks involved. This will allow the design team and clients to make informed decisions regarding the rest of the product design criteria.

Detailed Electronic Design Specifications

A specification outlining the required electronics hardware and software requirements is written to clearly communicate the project requirements to our engineers. This goes into great detail to ensure the outcome is the best it can be. The electronic specification will cover the technology and componentry that is critical as well as the functionality that the software and hardware must perform. In addition, the space constraints, shape of PCB and physical positions of things like buttons and screens are clear so that the electronics can be integrated into the mechanical housing perfectly.

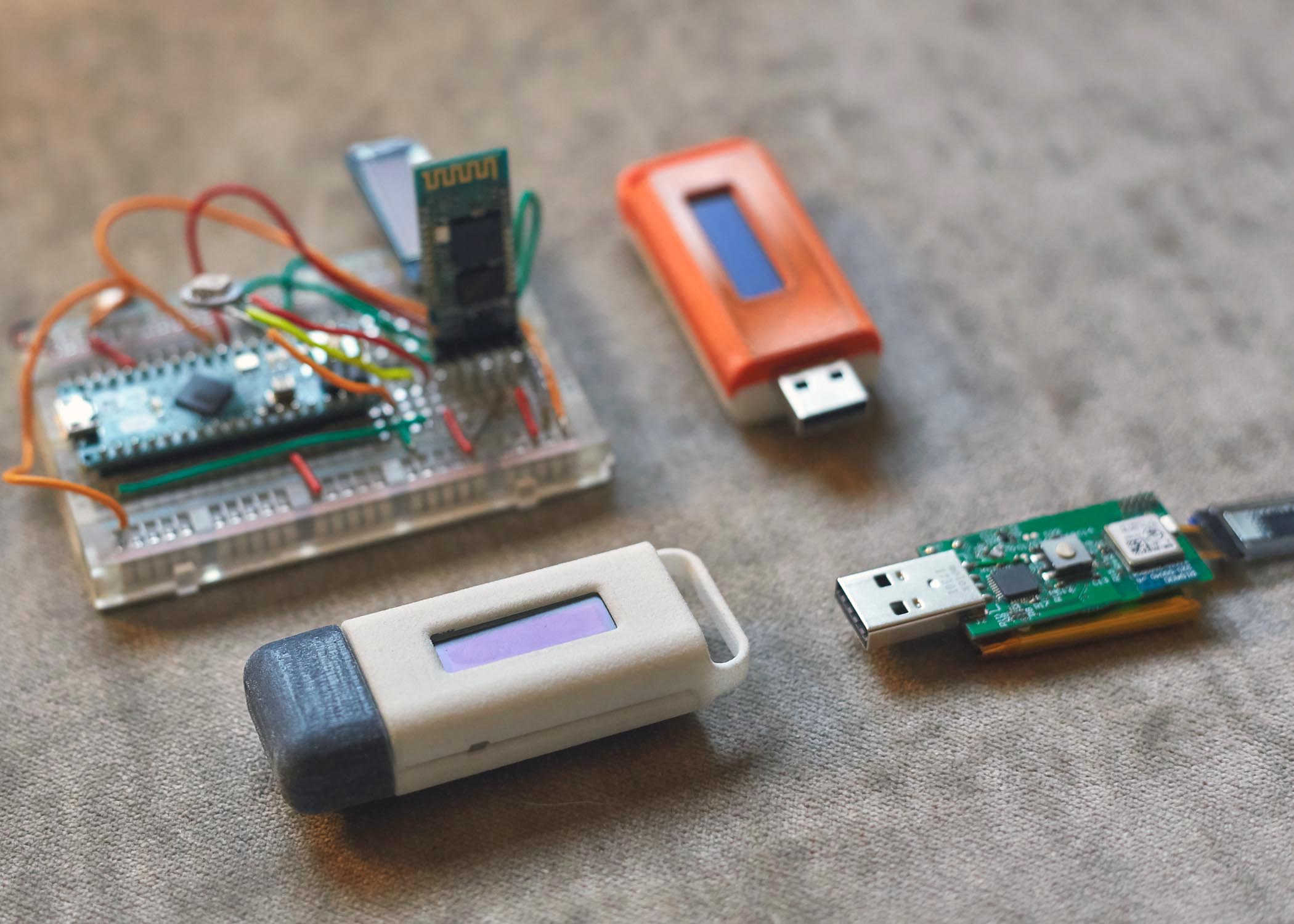

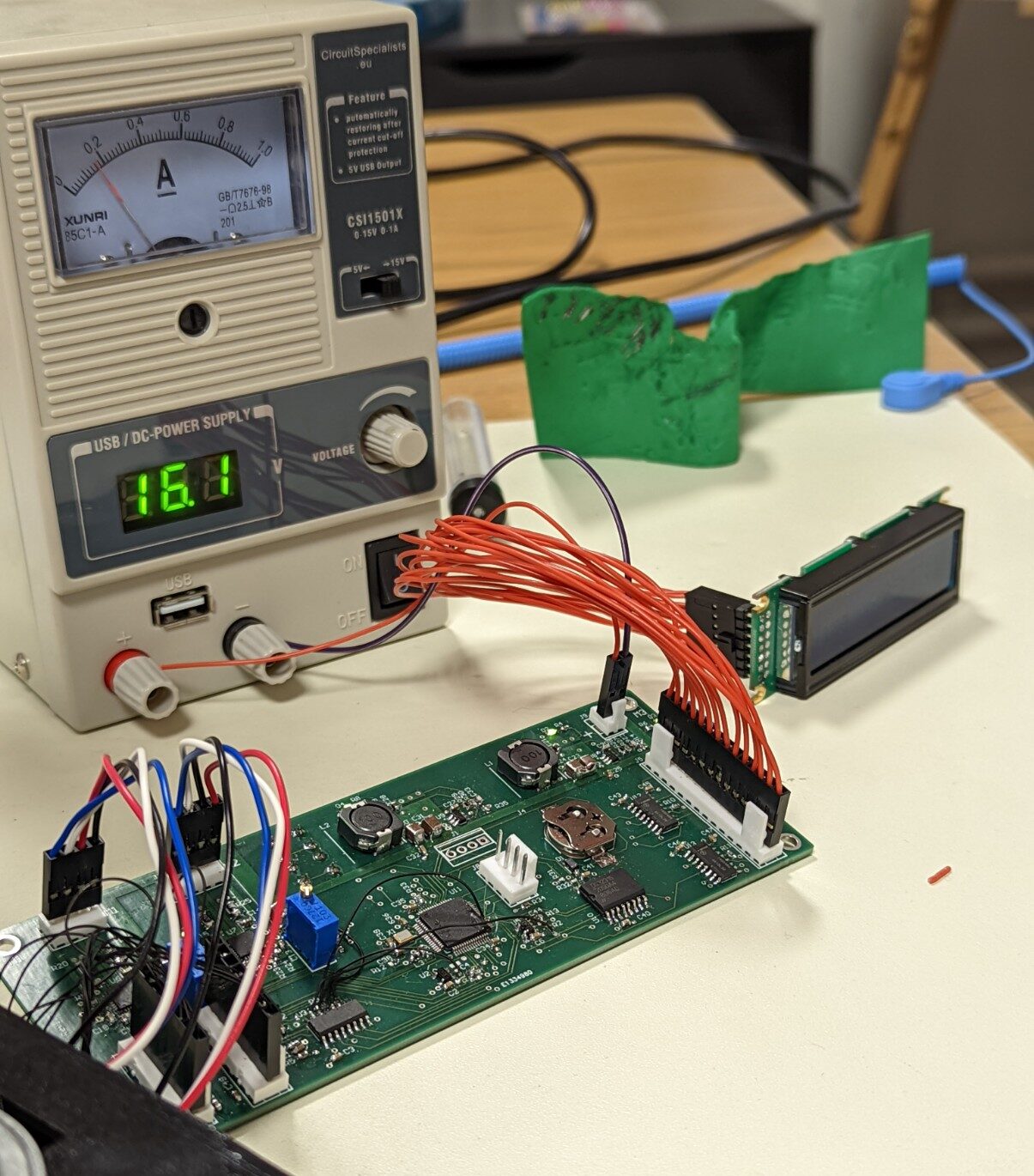

Design and Prototype of the Hardware

This may seem obvious but of course the hardware and software needs to then be designed and physically prototyped to allow for debugging and validation. Before further integration into the mechanical assembly and casings.

Often once the electronic elements are brought together with the rest of the product design the development process then becomes iterative depending on the testing of the prototypes and user feedback.

What Sets us Apart?

Early Consideration

We understand that to make a successful electronic product, early consideration for electronic components in critical. We work closely with electronic engineers throughout our normal design process to ensure there’s a seamless integration of electronics into the physical form or casing of a product. From considering space requirements during the Concept Design stages at the start of the process to ease of manufacturing and assembly at scale at the end of the design process. We work tirelessly to optimise our designs as best we can to achieve cost effective, engaging and ultimately successfully integrated electronic solutions.

Technical Expertise

We also appreciate the importance of technical expertise. Idea Reality excels in this area, with a huge network of experienced engineers that we can lean on for support in PCB (printed circuit board) design, firmware development and mobile app and web interface development. Not to mention our in-house team who have over 20 years of combined product design experience and who can tackle your electronic prototyping requirements such as mobile app design and low fidelity test rigs.

A User Centred Approach

Our focus on user centred electronic design also sets us apart from competitors, from concept design through to prototyping we pride ourselves on presenting intuitive user interfaces to our clients which provide an excellent experience for the end user. We can achieve this by drawing on our experience as well as iteratively developing and improving the experience throughout the prototyping stages.

Why Choose Us?

Our varied experience and technical know-how give us the ability to effectively design for electronics projects. Working closely with our electronics teams and defining the functionality from an early stage allows us to progress our client’s project swiftly and effectively.

If you’re looking to realise your electronic product idea into reality, don’t hesitate to get in touch and we’d love to help bring your idea to fruition.